[Translate to Englisch:]

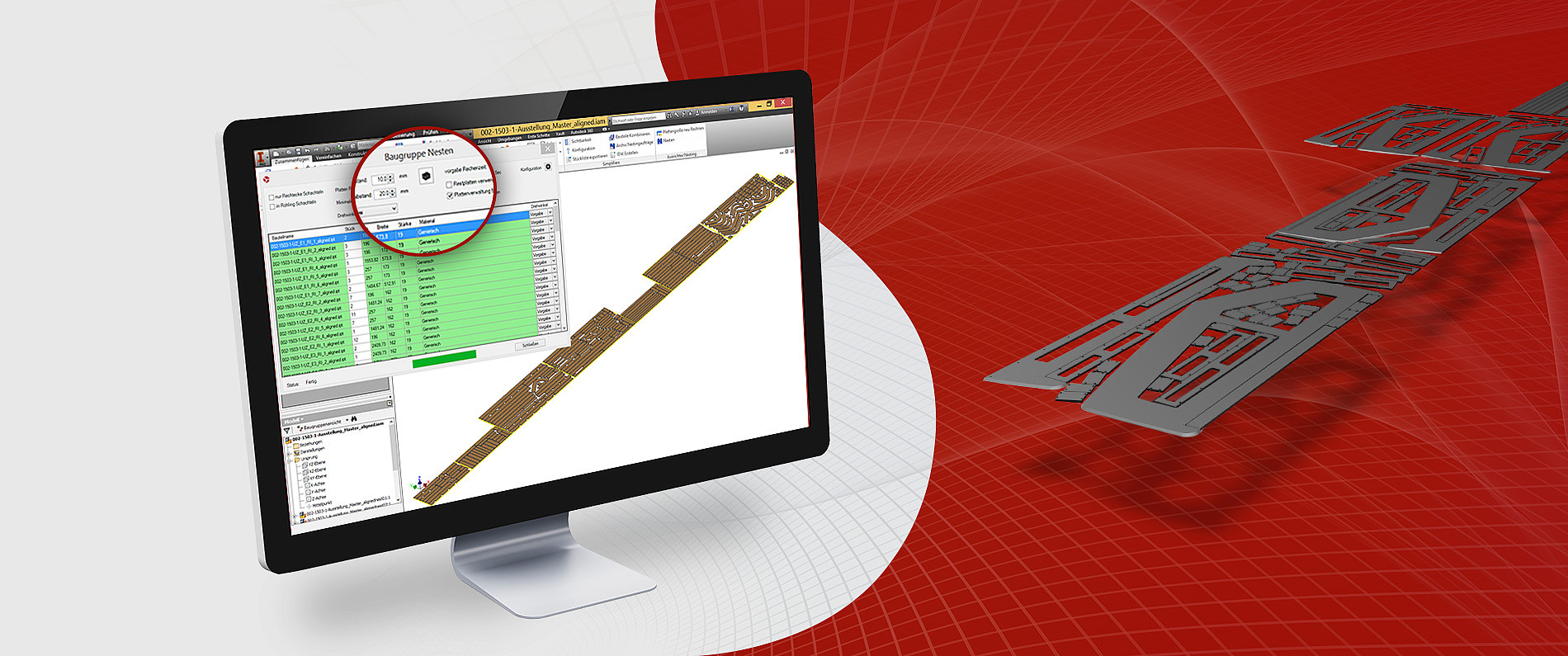

Simple-Nesting – die Nesting Software für Autodesk Inventor

Simple-Nesting to stir up the market for nesting solutions. Using Autodesk Inventor, it is now possible for the first time to optimize material utilization consistently throughout a project, from construction to CAM solution to production. Time-consuming exports and imports between different software solutions are now a thing of the past. Simple-Nesting is based on the newest and most advanced CAD/CAM nesting system.

Simple-Nesting allows you to save on material costs and manpower and optimize quality in the design and production process.

This pioneering extension module enables you to create a production assembly directly from a pre-engineered assembly. Simple-Nesting offers a variety of options to filter assemblies, in order to only manufacture parts with specific requirements in terms of thickness and material, for example.

Any given quantity of parts can be nested with any given geometry in an optimal and time-efficient manner. Available sheets, including residual material, may be used according to user-specific priorities. Cut-outs (holes) in parts are taken into consideration during the nesting process. Both distances between individual parts as well as rotation angles may be configured according to the user's requirements. This contributes considerably to reducing material waste. Different marginal conditions may be taken into consideration when placing the parts in the cutting pattern. Automatically generated cutting patterns offer better material utilization and flexibility compared to other systems in terms of material utilization which ensures that the data are optimally prepared for almost any cutting, stamping, or bending application.

Once nesting is completed, a main assembly with sub-assemblies (one assembly for every raw sheet) is created and saved according to the user's specifications. A nesting report is stored in the archive. From these reports, the user can retrieve the material utilization, the number of required raw sheets, etc.

Mit Simple-Nesting also enables rectangular nesting using the dimensions of the control volume. Of every nested assembly an IDW can be created automatically including the position numbers of the relevant parts.

Once the production assembly has been created, all parts will be arranged from left to right according to the relevant zero point in the assembly. Also, for the first time Simple-Nesting enables direct nesting of solid models in 3D.

Through seamless CAD integration Simple-Nesting allows nesting of complex assemblies within minutes which contributes to effectively calculating material requirements. Virtually all production machines can be controlled via Simple-Nesting, thanks to several CAM integration options in Autodesk Inventor.

Simple-Nesting includes following functions:

- Detailed nesting reports

- Export of nesting reports in *.pdf or *.csv or *.xls formats

- Option to print nesting reports

- Stock management and warehouse management

- Management of residual sheets

- Gap fillers

- Sheet nesting

- Nesting preview

- Several nesting strategies

- Sheet margin spacing

- nest Sheet holes

- Generate identical sheets

- Use of Multicore

- Polygon nesting

- Distance between parts

- Rotation angles freely selectable

- Group nesting

- Direction of parts

- Unlimited quantity of parts

- Unlimited raw material nesting

- Short computation times

Benefits of working with Simple-Nesting:

- Optimal raw material utilization through optimizing waste material

- Thanks to intelligent warehouse management, residual sheets can be used as well

- Detailed order tracking - including of finished projects

- Reduced unit costs through "part in part nesting"

- Highest precision through taking into account rolling direction of materials

- A one-stop solution for CAD software covering the whole process, from construction to manufacturing

Further Simplifiers products:

Using the Simple-Draw and Simple-Properties Properties modules, it is also possible to generate fully automated drawing exports of nested sheets. Position numbers and text blocks are filled in automatically which enables manufacturing to receive control drawings at the touch of a button in order to inspect and approve parts.

(0 36 95) 85 83 966